Printing is an important element for the success of any business. It plays an important role in enhancing the visual appeal of your product while maintaining cost efficiency. Two printing methods, offset and digital printing, are dominating the market. Each has different processes and offers unique benefits.

If you are a business owner, understanding Offset vs. Digital printing methods is significant for you. It will help you to align your brand’s objectives with production requirements. In this blog post, we will discuss these printing methods in detail and compare them in different aspects. This will help you to select the best option to fulfill your printing needs, so keep reading!

Overview of Offset Printing

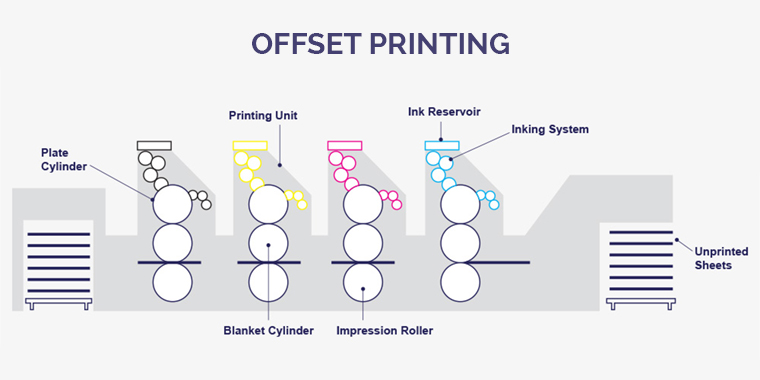

Offset printing is also known as offset lithography. It is a traditional printing method where images are transferred from metal plates to rubber blankets and then onto the printing surface. This is normally done on paper or cardboard.

Process

There are four steps in the offset printing process. Let’s review them:

- Plate Creation: Designs are etched onto metal plates, one is used for each color.

- Ink Application: Ink is applied to the plates.

- Transfer to Blanket: The inked image is transferred from the plate to a rubber blanket.

- Printing: The image is then pressed onto the packaging material.

Applications

Offset printing is widely used for:

- High-Volume Product Packaging: It is ideal for large runs of packaging materials, such as cereal boxes or beverage cartons

- Magazines and Catalogs: This printing method produces excellent-quality images and text for glossy publications.

- Brochures and Flyers: It is suitable for marketing materials that require sharp images and consistent colors.

- Labels and Stickers: Offset printing is used for the mass production of product labels with detailed designs.

- Books: Due to its efficiency in large volumes, offset printing is commonly used for printing books.

Read Also: What is Screen Printing?

Overview of Digital Printing

Digital printing is a modern printing method. Digital images are directly transferred onto various substrates in this type of printing. No metal plates are needed for digital printing.

Process

Three steps are involved in the process of digital printing. Let’s discuss them:

- File Preparation: Digital files are prepared using graphic design software.

- Printing: The digital image is sent directly to the printer, which applies toner or ink onto the packaging material.

- Finishing: Printed materials may undergo additional processes like cutting or laminating.

Applications

Digital printing is versatile and used for:

- Short-Run Packaging

It is ideal for limited edition products and market testing.

- Personalized Packaging

Digital printing allows customization, such as adding individual names or messages to your product packaging.

- Prototyping

This printing method is useful for creating packaging prototypes before mass production.

- Event-Specific Packaging

It is perfect for packaging custom-made for specific events or promotions.

- Variable Data Printing

It enables the printing of sequential numbers or unique barcodes for shipping labels.

Offset VS Digital Printing

Both these printing methods have many differences. Let’s have a look at them:

1. Equipment

In offset printing presses, metal plates, rubber blankets, and ink rollers are used as printing machines. Additional equipment may also be used for drying or finishing purposes.

However, there is no need for metal plates for digital press printing, making its process even simpler. It uses digital printers, toners, or inkjet cartridges and software.

2. Printing Quality

Offset printing provides high-resolution and sharp images with consistent colors. It is preferred for branding purposes and in-depth detailing of luxury gift boxes.

On the other hand, digital printing also offers good quality, but slight variations can occur. Some high-end digital printers can achieve near-offset quality, as well.

3. Cost

Due to the plate creation, offset printing has a higher initial setup cost. This is because resources are used to create plates.

However, for digital printing, there is no need for plates. Due to this, it has lower initial costs.

4. Turnaround Time

Offset Printing requires a longer time to set up because of plate-making, preparation, and drying. This makes it perfect to meet the deadlines.

In contrast, digital printing offers a faster turnaround time, as it prints directly from digital files. Due to this, it is ideal for on-demand or urgent printing needs.

5. Volume of Project

Offset Printing is best suited for printing projects of larger scale, where thousands of copies are needed. It is cost-effective for these projects. In contrast, digital Printing works best for short to medium print runs. This makes it a great choice for test prints, prototypes, or custom packaging products.

6. Material Selection

Offset Printing can be applied to different types of materials, such as paper, cardboard, and plastic. On the other hand, digital printing supports numerous types of paper and some synthetic materials. But it has fewer options compared to offset printing.

7. Customization Options

Offset Printing offers limited customization because once plates are made, changing the design requires new plates, which can be costly. While digital printing is highly customizable. It also allows variable data printing (VDP). This makes it ideal for personalized packaging, barcodes, names, and serial numbers.

8. Environmental Impact

Offset printing uses more ink and chemicals. So it generates more waste such as plates and excess paper. In comparison, digital printing produces less waste and uses fewer materials. Due to this, it is considered more eco-friendly and used for sustainable packaging.

In recent times, digital technology has been replacing printing plates. This is because eco-conscious brands prefer digital printing as a greener option.

Also read: What is Lithographic Printing

Final Thoughts

We have covered the discussion over offset vs. digital printing. Selecting the appropriate printing method is important to achieve optimal results. Both these printing methods offer unique advantages that are important for different industries.

Are you looking for a high-end printing and packaging partner for your next project? Worry not! At Custom Designs Boxes, we deliver high-quality printing solutions for your packaging requirements. Our expertise ensures that your products reflect the quality and integrity of your brand. Contact us via email today at sales@customdesignsboxes.com to experience excellence in packaging.