Colors play a substantial role in packaging, as they influence the buying decisions of customers and help to build your brand’s identity. CMYK is one of the most commonly used color models in the printing industry. But you might wonder what CMYK stands for and why it is important in the packaging industry.

Knowing about these queries will help you to make wise decisions to fulfill your printing requirements if you are a business owner or want to start one. This blog post will explain CMYK printing in detail, examine its process benefits, and compare it with other color models. So, let’s start!

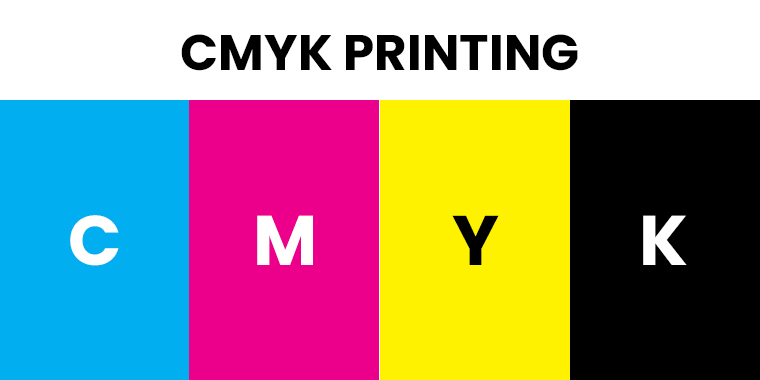

What Does CMYK Mean?

CMYK stands for Cyan, Magenta, Yellow, and Black (Key). This is also the standard printing order. It ensures proper layering and accurate color reproduction. This four-color process printing method is widely used in the packaging industry. These colors are combined in different percentages to create many other colors for printed materials like custom-printed hang tags.

CMYK Printing Process

CMYK printing works by layering tiny dots of inks on paper boxes or other packaging material. The combination of these dots creates different shades and colors.

4 Steps of the CMYK Printing Process

CMYK Printing process has the following four steps:

Step 1. Design Preparation

The artwork is created in CMYK mode using software like Adobe Photoshop or Illustrator.

Step 2. Plate Setup (for Offset Printing)

In traditional printing, separate plates are made for each CMYK color.

Step 3. Ink Application

The printer applies layers of ink in precise patterns.

Step 4. Drying & Finishing

The ink dries, and additional coatings or finishes may be applied for durability.

CMYK Printing in Packaging

CMYK printing is extensively used in the packaging industry. This is due to the efficiency it offers. Let’s discuss why:

- Versatile: Works on various materials like cardboard, corrugated boxes, and labels.

- Cost-Effective: Ideal for high-volume production.

- Eco-Friendly: Modern CMYK printing uses less waste and sustainable inks.

- High-Quality Images: Produces detailed and vibrant packaging designs.

Read Also: Offset VS Digital Printing

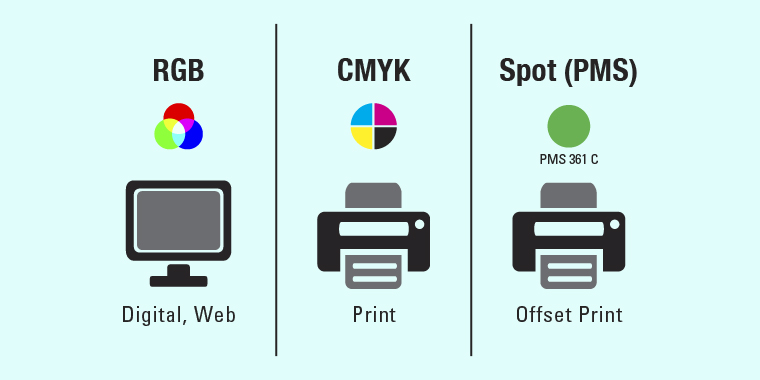

CMYK Vs. RGB Vs. PMS

Let’s discuss the differences between CMYK color model and other color models:

1. Comparing CMYK Screen Printing and RGB Printing

Many designers get confused about using CMYK or RGB for print. The answer depends on the medium you use. RGB is used for digital screens. It produces vibrant colors through light. In contrast, CMYK is used for printing. It creates colors by mixing ink on paper.

A design in RGB is converted to CMYK before printing. This ensures color accuracy. It is done for packaging sleeves and other forms of packaging.

2. Comparing CMYK Colors and PMS Colors

CMYK is a reliable color process, but some brands may need exact matching of colors. Such as banks for their credit card boxes. PMS colors are perfect for this purpose.

CMYK printing uses four inks to create different shades. Slight color variations may occur in it. Meanwhile, Pantone printing uses pre-mixed inks for accurate color matching.

Pantone is converted into CMYK for Printing. While CMYK can replicate many Pantone colors, some shades may not match perfectly.

Also read: Why Offset Printing is Still the Best Choice For High-Quality Prints

Wrapping Up:

CMYK printing is the backbone of the packaging industry. It provides reliable and cost-effective color reproduction for brands worldwide. It works well for rigid setup boxes. If you’re designing boxes, labels, or marketing materials, understanding CMYK ensures your prints look professional and vibrant.

We at Custom Designs Boxes use CMYK printing to provide vibrant results on personalized packaging solutions. Get expert opinions from our experienced professionals. Contact us today via email at sales@customdesignsboxes.com to get the best printing results and stand out from the rest of the market.