Most people think about packaging in terms of its outer appearance, including its framework, aesthetic, and branding. However, what's inside the cardboard layers is equally important for everyone involved in production, shipping, online shopping, or product packaging.

Remember, a box's performance is greatly influenced by its interior structure, known as a corrugated flute, which is the wavy sheet positioned between liners. From safety, rigidity, and stacking strength to print surface and cost efficiency, choosing the right flute can make the difference between a box that arrives crisp and one that arrives crushed.

Being familiar with flutes is the cornerstone of smart packaging choices, whether you're shipping fragile products or creating high-end packaging for store shelves.

Everything you need to know about corrugated flutes is broken down in this guide, including corrugated flute kinds, sizes, thickness, performance factors, and even a corrugated flute chart to help you pick the best choice.

What Is a Corrugated Flute?

The arch-shaped structure that runs between the inner and outer layers of corrugated board is called a corrugated flute. It provides the box with its distinctive structure, resilience, and cushioning. Air pockets are created by the curved pattern, which improves stacking strength and helps absorb shock during the ride.

In simple terms:

- The liners provide surface protection

- The flutes provide rigidity and cushioning

Because of this combination, corrugated cardboard is more durable, impact-resistant, and protective than ordinary flat cardboard. However, the sort of flute utilized affects how well a corrugated box performs. For this reason, it's crucial to acknowledge flute variants.

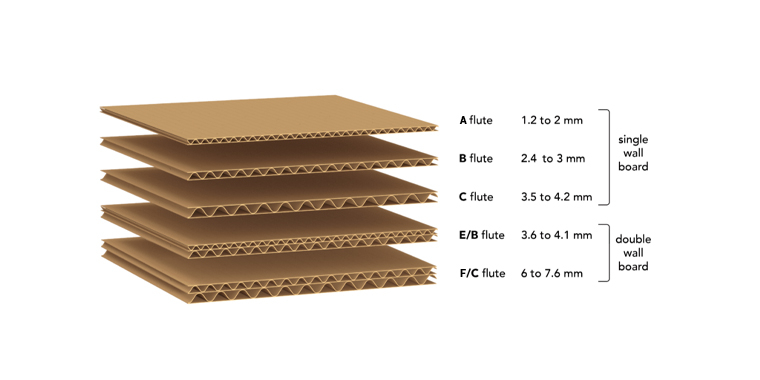

Understanding Corrugated Flute Sizes

The height and number of the fluting waves are referred to as corrugated flute sizes. Despite having an identical look, the two boxes may differ greatly in the following ways due to internal fluting:

- Power

- Cushioning

- Resistance to compression

- Print quality

- Smoothness of the surface

While smaller flutes provide better printing and structure with less bulk, larger flutes offer additional cushioning.

When deciding on flute size, take into account the following factors:

- Product weight

- Fragility of contents

- Shipping distance

- Handling conditions

- Desired surface finish

- Packaging cost

- Storage and stacking requirements

Larger flutes are preferable for heavy or delicate objects. Smoother-surfaced, finer flutes are for high-end shop displays, electronics, and cosmetics.

Corrugated Flute Types & Their Applications

There is no one-size-fits-all packaging. The right flute is essential since different products and industries demand distinct designs. The most popular forms of corrugated flute are listed below, along with their advantages, ideal uses, and traits.

A Flute Corrugated

One of the first and thickest flute forms is the corrugated flute. It is frequently utilized for bulky shipping boxes and offers superior cushioning.

Key Features

- Thick structure

- Excellent stacking capability

- Outstanding absorption of shock, pressure, and sharp falls

Best Uses

- Industrial packaging

- Shipping fragile products

- Double-wall construction

- Packaging that can be exposed to rough handling

When protection is more important than style or portability, the A-flute usually gets preferred.

B Flute Corrugated

Although the B flute corrugated is less thick than the A flute, it is still quite adaptable. It gives a smoother printing surface and better stacking strength. In businesses that need packaging with resilience without being overly bulky, this flute has become well-liked.

Key Features

- Small flute size

- Good uniformity of the surface

- Strong defence against crushing

Best Uses

- Die-cut boxes

- Retail packaging

- Display boxes

- Shelf-ready packaging

C Flute (For completeness)

One of the most popular and extensively used corrugated flute profiles is the C flute. It is a reliable option for transport, retail, and promotional packaging because it provides an optimal balance of strength, crush resistance, and printing adaptability.

Key Features

- Structure with a medium thickness

- Strong resistance to bending and stacking

- Decent protection and cushioning for the majority of product types

- The best surface for labelling, branding, and printing

Best Uses

- Standard shipping carton

- Retail and display boxes

- Food and beverage packaging

- Single-wall packaging demanding strength and presentation

E Flute Corrugated

Because the E flute corrugated is considerably thinner, it is suited for premium retail boxes that need to be printed to a high standard. In businesses where presentation is just as important as protection, e-flute is a favorite.

Key Features

- Smooth surface for high-quality printing

- Lightweight but structurally resilient

- Excellent for branding and customization

Best Uses

- Cosmetic packaging

- Electronics packaging

- Small luxury boxes

- Retail displays

F Flute Corrugated

Thinness is further enhanced by the F flute corrugated! Without compromising strength, it provides a fine surface that supports complex printing and detailing. F-flute is usually chosen by brands that prioritize high-end unpacking experiences.

Key Features

- Carries a very fine fluting

- Light in nature

- Gives an opulent vibe

Best Uses

- Jewelry boxes

- Gift packaging

- Compact product cartons

- Design-focused retail packaging

D Flute Corrugated

Although less common, the D flute corrugated is exceptionally efficient. It provides a balance between a printed surface and stability. D-flute stands out for packaging that requires both toughness and aesthetic quality because of its hybrid character.

Key Features

- Mid-range flute height

- Strength comparable to the B-flute

- Smoother surface for branding

Best Uses

- Packaging needing print appeal & strength

- Electronics

- Consumer goods

- Branded shipping cartons

N Flute Corrugated

Among the thinnest flutes available, N flute corrugated brings a sleek and modern look to packaging without compromising strength. N-flute is gaining popularity in industries where sleekness, space-saving, and sustainability are priorities.

Key Features

- Ultra-thin

- Very smooth surface

- Supports high-definition prints

Best Uses

- Folding cartons

- Minimalist luxury packaging

- Retail displays

- Compact branded shipping cartons

Corrugated Flute Thickness: Why It Matters

Each flute's height is referred to as corrugated flute thickness, and although the millimetre deviation seems insignificant, it has a significant impact on box performance.

For heavy goods that need additional protection during vigorous handling or transportation, thicker flutes offer superior cushioning, increased impact resistance, and greater stacking strength. Thinner flutes, on the other hand, are suited for specialized retail packaging where aesthetics and lightweight convenience are important since they provide a smoother print surface, less weight, and less bulk.

The ideal flute thickness essentially depends on the weight, fragility, and shipment requirements of the object.

Corrugated Cardboard Flute Strength Comparison

There is a best flute for every product, but there isn't a single "best" flute. Various flute profiles perform well under different real-world situations:

For Shipping & Warehousing

A-flute and C-flute work best for shipping and warehousing because of their padding and stackability.

Long-distance cargo is best protected by double-wall combinations, such as A + B.

For E-commerce

Because they provide a mix of strength, price, and surface printability, B and E flutes are often used for e-commerce.

For Retail Display & Branding

The package seems clean, professional, and refined because of the finer surfaces that E, F, and N flutes offer for outstanding graphics.

For Luxury or Boutique Products

F and N flutes are perfect for upscale or boutique products - thanks to their visually appealing shape and slim profile, thereby improving the unboxing experience.

|

Flute Type | Approx. Properties | Main Benefits | Best For |

| A Flute | Thick with large. Noticeable fluting | Unrivalled cushioning & stacking strength | Industrial use, bulky items, and heavy shipping of multi-product boxes |

| B Flute | Medium height | Impressive crush and tear resistance, along with satisfactory printability | E-commerce, displays, shipping |

| C Flute | Medium thickness |

Optimized for unbeatable strength and a neat, tidy surface | General-purpose packaging |

| E Flute | Thin and fine | Top-class printable, smooth surface while boasting a stable structure | Expensive-looking retail packaging |

| F Flute | Very fine | High-fidelity graphics for ultimate branding | Luxury, gift & product boxes |

| D Flute | Mid-range | A mix of strength and print appeal | Consumer and branded cartons |

| N Flute | Ultra-thin | Chic appearance, no-smudge printing, and light to support easy use |

Compact and premium packaging |

How to Choose the Best Corrugated Flute

Choosing the right corrugated flute means balancing strength, branding, cost, and shipping needs.

Level of Safety Required

The first consideration is product weight and fragility, since this affects how much protection your packaging must provide. A or B flutes, which offer great cushioning and stacking strength, are typically better suitable for heavy or fragile objects. Lightweight things benefit from thinner E, F, or N flutes that reduce bulk and provide an uncluttered presentation. Lastly, medium-weight items normally function with B or C flutes.

Shipping Demands

Next, consider how the box will be transported. Thicker flutes are more secure as well as reliable if the product will be carried over long distances or constantly stacked with loads. Thinner flutes, on the other hand, offer sharper print results and a more polished surface. Opt for it if the box is intended for store shelves or display spots.

Visual Charm

Aesthetics are equally important. Choose smoother flute options, such as E, F, or N, if your business depends on vibrant colours, complex designs, or high-end finishing. Why? Because each produces the optimum print quality!

In Relation to Brand

The flute you select might also affect how people perceive your brand:

- Professional-grade, durable shipping → B or C flute

- Luxury reveal of your product → F or N flute

- Attention-grabbing store presence → E flute with premium printing

Budgeting

Efficiency in terms of cost also matters. Thinner flutes generally accommodate more boxes on a pallet, need less material, and take up less space for storage. Thicker flutes, however, might lower damage expenses, particularly for delicate goods.

Green Practices

Lastly, present packaging decisions are influenced by sustainability. Finer flutes are preferred by many businesses in order to reduce material consumption and increase shipping efficiency. Well, it helps lessen the impact on the environment while preserving a strong brand image.

Conclusion

Finding the most suitable corrugated flute is a business strategy as much as a packaging choice. Making the incorrect decision can result in packaging that appears cheap and amateurish, smashed products, or increased return rates. With the correct flute, you can:

- Structural support

- Shock resistance

- A perfect surface for printing

- Cost and storage efficiency

- A better brand experience

There is a flute for every product and brand, ranging from an A flute corrugated for industrial strength to an N flute corrugated for upscale folding cartons.

Packaging plays a role in your initial impression in today's competitive market. Choose wisely and strategically with Custom Designs Boxes, and allow your corrugated cardboard flute to remain secure, show off, and function as it should.